-

Demiryolu Döküm Parçaları

-

Demiryolu Dövme Parçaları

-

Demiryolu Askı Sistemi

-

Demiryolu Frenleme Sistemi

-

Demiryolu Taşıma İç Mekanları

-

Demiryolu Tekerleği Ve Aks

-

Tren Bağlayıcı

-

Tren Geçidi

-

Demiryolu Çekiş Sistemi

-

Lokomotif Yedek Parçaları

-

Demiryolu İle İlgili Ekipmanlar

-

Demiryolu Fren Valfi

-

Demiryolu rayı parçaları

-

JonathalarÖnerdikleri kuplör eskilerinin yerine oldukça uygundur. Fiyat makul ve onları almak için sabırsızlanıyoruz.

JonathalarÖnerdikleri kuplör eskilerinin yerine oldukça uygundur. Fiyat makul ve onları almak için sabırsızlanıyoruz. -

JoseAldığım DF8B yedek parçalarının hepsi doğru. Teslim süresi hızlı ve ne zaman bir sorunum olsa Sunny bana yardım etmek için her zaman burada. Ona çok teşekkür ediyor ve gelecekteki işbirliğimizi tekrar sabırsızlıkla bekliyoruz.

JoseAldığım DF8B yedek parçalarının hepsi doğru. Teslim süresi hızlı ve ne zaman bir sorunum olsa Sunny bana yardım etmek için her zaman burada. Ona çok teşekkür ediyor ve gelecekteki işbirliğimizi tekrar sabırsızlıkla bekliyoruz.

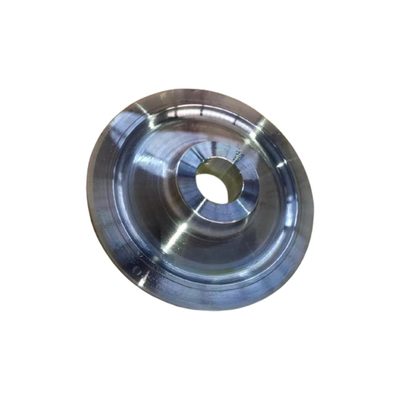

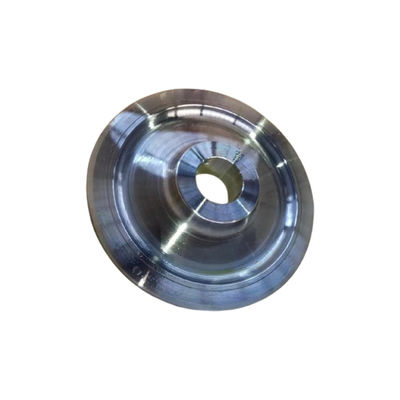

High Quality AAR Anti-corrosive Treatment Wheels for Freight Wagon

| Çekim Gücü | 790-980 | Uzunluk | ≥ ((8-12) |

|---|---|---|---|

| Farklı Nominal Dia | ≤0.5MM | İki Tekerleğin Simetri Derecesi | ≤1mm |

| Jant HB | 246-307 | Flanş Çapı | 861±1 |

| Göbek uzunluğu | 155±1 | Jant genişliği | 130±1 |

| İç/Dış Çember Çapı. | 709±1 | İç MesafeGöbek ve jant arası | 10±1 |

| Vurgulamak | AAR Anti-korroziv tedavi tekerlekleri,Anti-corrosive Treatment Wheels |

||

Product View

Train wheels are the key components of railway vehicles, they bear the important role of supporting the body, transferring the load and providing traction. Modern train wheels are usually made of high-strength steel materials to ensure adequate durability and safety.

Product Standard

- AAR M-107/M-208 WHEELS, CARBON STEEL SPECIFICATION

- EN 13262 RAILWAY APPLICATIONSWHEELS - PRODUCT REQUIREMENTS

- BS 5892-3 SPECIFICATION FOR MONOBLOC WHEELS FOR TRACTION AND TRAILING STOCK

- JIS E5402-2 RAILWAY ROLLING STOCK-SOLID STEEL WHEEL

- TB/T 2817 TECHNICAL SPECIFICATION OF WROUGHT STEEL SOLID WHEEL FOR RAILWAY FREIGHT CAR

![]()

1.Superior Material: Made from special high-strength steel with strict chemical composition control and heat treatment processes, providing excellent wear resistance and fatigue performance.

2.Advanced Design: The wheel design utilizes Computer-Aided Engineering (CAE) technology to optimize the structure of the wheel rim and tread, enhancing load capacity and operational stability.

3.Precision Machining: High-precision CNC machining ensures precise geometric dimensions and superior dynamic balance, reducing vibration and noise during operation.

4.Wear Resistance: The surface undergoes a special hardening treatment to form a robust protective layer, significantly improving the wheels' wear resistance and extending their service life.

5.Safety Performance: Each wheel is subjected to rigorous non-destructive testing and static load testing to ensure there are no defects, maintaining stability and safety during high-speed operation.

6.Environmentally Friendly and Energy-Saving: Optimized design and manufacturing processes reduce energy loss during operation, helping to improve the train's energy efficiency ratio and lower operational costs.

7.Wide Application: Suitable for various types of railway vehicles, including high-speed trains, freight trains, subways, and light rails, meeting the demands of different working conditions.

Product advantage

Certificated with AAR

100% automated Ultrasonic test as well as magnetic particle

Less MOQ requirement

Superior hardness

Product structure

![]()